Gaadhida Horizontal

Warshada dejinta hilibka, heerkulka deegaanka waxaa lagu xakameynayaa 21°C, waxaana la qaatay HS-100 khadka dejinta hilibka.Celceliska miisaanka hilibku waa 60kg/M2.Ballaca suunka waa 600mm, wadarta guud ee suunkana waa 30M oo nashqad siman ah.Xawaaraha suunka qaada qaada waa 18M/daqiiqo marka la joogo huurka iyo deegaanka qabowga.Gaadhi-qaaduhu wuxuu ku bilaabmayaa dejinta oo ma jiro xaalad urursan.Waxay qabataa sprockets leh 8 ilkood oo dhexroor ah 192mm, iyo 38mm x 38mm usheeda dhexe ee birta ah.Habka xisaabinta ee khuseeya waa sida soo socota.

Xisaabinta xiisadda aragtida unugga - Qaaxada

| FORMULA | TB =〔 ( WP + 2 WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔 ( 60 + ( 2 × 8.6 ) × 0.12 〕× 30 = 278 (kg / M) | |

| Sababtoo ah ma aha gudbinta ururinta, Wf waa la iska indho tiri karaa. |

Xisaabinta cutubka wadarta xiisadda - TW

| FORMULA | TW = TB × FA |

| TW = 278 × 1.0 = 278 (Kg / M) |

Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

| TA = 1445 × 1.0 × 0.95 = 1372.75 (Kg / M) | |

| Sababtoo ah qiimaha TA wuu ka weyn yahay TW, Sidaa darteed, in lagu qaato HS-100 waa doorasho habboon. |

Fadlan tixraac kala dheereynta Sprocket ee HS-100 ee cutubka Sprockets Drive;fogaanta ugu badan ee sprocket waa ku dhawaad 140mm naqshadahan.Labada dhinac ee marawaxadaha wadida/Idler waa in lagu dhejiyaa 3 xabo oo xabo ah.

-

Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TW + SW ) × BW |

| SL = ( 278 + 11.48 ) × 0.6 = 173.7 (Kg) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 38mm × 38mm uu yahay badbaado iyo xulasho habboon. | |

| FORMULA | DS = 5 × 10-4 × ( SL x SB3 / E x I) |

| DS = 5 × 10-4 × [ (173.7 × 7003) / ( 19700 × 174817 ) ] = 0.0086 | |

| Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka. |

-

Xisaabinta torque usheeda dhexe - TS

| FORMULA | TS = TW × BW × R |

| TS = 10675 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 50mm × 50mm uu yahay badbaado iyo xulasho habboon. |

-

Xisaabinta xoogga faraska - HP

| FORMULA | HP = 2.2 × 10-4 × [( TS × V) / R] |

| HP = 2.2 × 10-4 × [ ( 10675 × 10 ) / 66.5] = 0.32 (Hp) | |

| Guud ahaan, tamarta makaanikada ee wareejinta wareejintu waxay lumin kartaa 11% inta lagu jiro hawlgalka. | |

| MHP = [0.32 / (100 - 11)]× 100 = 0.35 (Hp) | |

| Qaadashada matoorka wadista 1/2HP waa doorashada saxda ah. |

Waxaan cutubkan ku taxnay tusaalooyin wax ku ool ah tixraacaada, waxaanan ku hagayaa inaad xisaabiso tijaabinta iyo xaqiijinta natiijada xisaabinta.

Gaadhi-wade Xarunta

Gaadiidleyda la ururiyey waxaa badanaa lagu dabaqaa warshadaha cabitaanka.Naqshadeynta gaadiidku waa 2M oo ballac ah iyo 6M oo dhererkeedu dhan yahay.Xawaaraha shaqo-qaaduhu waa 20M/min;waxay ka bilaabataa xaalada alaabooyinka ku urura suunka waxayna ku shaqeeyaan 30 ℃ jawi qalalan.Rakibaadda suunka waa 80Kg/m2 alaabada daabuladuna waa gasacadaha aluminium ee cabitaanka ku dhex jira.Xirmooyinka xirmooyinka waxay ka samaysan yihiin walxo UHMW, waxaana la qaatay Taxanaha 100BIP, bir-fudud bir ah oo leh 10 ilkood, iyo bir wadida/shaaf aan shaqaynayn oo cabbirkeedu yahay 50mm x 50mm.Hababka xisaabinta ee khuseeya waa sidan soo socota.

-

Gaadhida aruurinta - Wf

| FORMULA | Wf = WP × FBP × PP |

| Wf = 80 × 0.4 × 1 = 32 (Kg / M) |

-

Xisaabinta xiisadda aragtida unugga - Qaaxada

| FORMULA | TB =〔 ( WP + 2 WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔 ( 100 + ( 2 × 8.6 ) × 0.12 + 32 〕× 6 + 0 = 276.4 ( kg / M ) |

-

Xisaabinta wadarta xiisadda unugga- TW

| FORMULA | TW = TB × FA |

| TW = 276.4 × 1.6 = 442 (Kg / M) | |

| TWS = 2 TW = 884 Kg/M | |

| TWS waayo waa udub dhexaadka |

-

Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

| TA = 1445 × 1.0 × 0.95 = 1372 (Kg / M) | |

| Sababtoo ah qiimaha TA wuu ka weyn yahay TW, Sidaa darteed, in lagu qaato HS-100 waa doorasho habboon. |

-

Fadlan tixraac kala dheeraynta Sprocket ee HS-100 ee cutubka Sprockets Drive;fogaanta ugu badan ee sprocket waa ku dhawaad 120mm naqshadahan.

-

Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TW + SW ) × BW |

| SL = ( 884 + 19.87 ) × 2 = 1807 (Kg) | |

| DS = 5 × 10-4 [( SL × SB3) / ( E × I ) ] | |

| DS = 5 × 10-4 × [ ( 1791 × 21003 ) / ( 19700 × 1352750 ) ] = 0.3 mm | |

| Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka. |

-

Xisaabinta torque usheeda dhexe - TS

| FORMULA | TS = TWS × BW × R |

| TS = 884 × 2 × 97 = 171496 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 50mm × 50mm uu yahay badbaado iyo xulasho habboon. |

-

Xisaabinta xoogga faraska - HP

| FORMULA | HP = 2.2 × 10-4 [( TS × V) / R] |

| HP =2.2 ×10-4 × [( 171496 × 4) / 82] = 1.84 (HP) | |

| Guud ahaan, tamarta makaanikada ee wareejinta wareejintu waxay lumin kartaa 25% inta lagu jiro hawlgalka. | |

| MHP = [ 1.84 / ( 100 - 25 ) ] × 100 = 2.45 ( HP ) | |

| Qaadashada mootada wadista 3HP waa doorashada saxda ah. |

Jid wareejinta

Habka gudbinta leexleexadu waxa uu muujinayaa sawirka kore waxa loogu talagalay in lagu dhaqo khudaarta.Dhererkeeda toosan waa 4M, wadarta guud ee alaab-qaaduhu waa 10M, ballaca suunkana waa 900mm.Waxay ku shaqeysaa jawi qoyaan leh oo xawlihiisu yahay 20M/daqiiqo si loogu qaado digir dhan 60Kg/M2.Xirmooyinka xirxiran waxay ka samaysan yihiin walxo UHMW, suunka qaaduhuna waa HS-200B oo leh 50mm(H) duulimaadyo iyo 60mm(H) ilaalo dhinac ah.Nidaamku wuxuu ku bilaabmaa xaalada isagoon wadan alaab, wuxuuna sii shaqeeyaa ugu yaraan 7.5 saacadood.Waxa kale oo ay ku korsanaysaa xabagyo leh 12 ilkood iyo bir bir ah oo ah 38mm x 38mm darawalnimo/dhicir aan shaqaynayn.Hababka xisaabinta ee khuseeya waa sidan soo socota.

- Xisaabinta xiisadda aragtida unugga - Qaaxada

| FORMULA | TB =〔 ( WP + 2WB ) × FBW + Wf 〕× L + ( WP × H ) |

| TB =〔( 60 + ( 2 × 4.4 ) × 0.12 + 0 ) 〕× 10 + ( 60 × 4 ) = 322.6 ( kg / M ) | |

| Sababtoo ah ma aha gudbinta ururinta,Wf waa la iska indho tiri karaa. |

- Xisaabinta cutubka wadarta xiisadda - TW

| FORMULA | TW = TB × FA |

| TW = 322.6 × 1.6 = 516.2 (Kg / M) |

- Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

| TA = 980 × 1.0 × 0.95 = 931 | |

| Sababtoo ah qiimaha TA ayaa ka weyn TW;sidaas darteed, qaadashada HS-200BFP suunka gudbinta waa doorasho sax ah oo badbaado leh. |

- Fadlan tixraac kala dheereynta Sprocket ee HS-200 ee cutubka Sprockets Drive;kala dheeraynta ugu badan ee sprocket waa ku dhawaad 85mm naqshadahan.

- Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TW + SW ) × BW |

| SL = ( 516.2 + 11.48 ) × 0.9 = 475 Kg | |

| FORMULA | DS = 5 × 10-4 × [ ( SL x SB3 ) / ( E x I ) ] |

| DS = 5 × 10-4 × [ ( 475 × 10003 ) / ( 19700 × 174817 ) ] = 0.069 mm | |

| Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka. |

- Xisaabinta torque usheeda dhexe - TS

| FORMULA | TS = TW × BW × R |

| TS = 322.6 × 0.9 × 49 = 14227 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 38mm × 38mm uu yahay badbaado iyo xulasho habboon. |

- Xisaabinta xoogga faraska - HP

| FORMULA | HP = 2.2 × 10-4 × [( TS × V) / R] |

| HP = 2.2 × 10-4 × [ ( 14227 × 20 ) / 49] = 1.28 (HP) | |

| Guud ahaan, tamarta makaanikada ee wareejinta wareejintu waxay lumin kartaa 20% inta lagu jiro hawlgalka. | |

| MHP = [ 1.28 / ( 100 - 20 ) ] × 100 = 1.6 ( HP ) | |

| Qaadashada matoorka wadista 2HP waa doorashada saxda ah. |

Gaadhi-wareegaya

Nidaamka wareejinta ee sawirka sare ku yaal waa 90 darajo rogid. Xargaha dariiqa soo laabashada iyo dariiqa qaadida labaduba waxay ka samaysan yihiin walxo HDPE.ballaca suunka wax qaada waa 500mm;Waxay qabataa suunka HS-500B iyo sprockets leh 24 ilkood.Dhererka qaybta orodka tooska ah waa 2M ee dhamaadka shaqo la'aanta iyo 2M dhamaadka wadista.Dhexdiisu waa 1200mm.Qodobka is jiid-jiidka ee xargaha iyo suunka waa 0.15.Walxaha daabula waa sanduuqyo kartoon oo cabbirkoodu yahay 60Kg/M2.Xawaaraha hawlgalku waa 4M/min, wuxuuna ku shaqeeyaa jawiga qalalan.Xisaabinta la xidhiidha waa sidan soo socota.

-

Xisaabinta wadarta xiisadda unugga - TWS

| FORMULA | TWS = ( TN ) |

| Wadarta xiisadda qaybta wadista ee habka qaadista. | |

| T0 = 0 | |

| T1 = WB + FBW × LR × WB | |

| T1 = 5.9 + 0.35 × 2 × ( 5.9 ) = 10.1 | |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Xiisadda qaybta leexinta ee habka soo noqoshada.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc. | |

| T2 = ( Ca × T2-1 ) + ( Cb × FBW × RO ) × WB | |

| TN = ( Ca × T1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( 1.27 × 10.1 ) + ( 0.15 × 0.35 × 1.7 ) × 5.9 = 13.35 | |

| FORMULA | TN = TN-1 + FBW × LR × WB |

| Xiisadda qaybta tooska ah ee habka soo noqoshada. | |

| T3 = T3-1 + FBW × LR × WB | |

| T3 = T2 + FBW × LR × WB | |

| T3 = 13.35 + 0.35 × 2 × 5.9 = 17.5 | |

| FORMULA | TN = TN-1 + FBW × LP × ( WB + WP ) |

| T4 = T4-1 + FBW × LP × ( WB + WP ) | |

| T4 = T3 + FBW × LP × ( WB + WP ) | |

| T4 = 17.5 + 0.35 × 2 × ( 5.9 + 60 ) = 63.6 | |

| Xiisadda qaybta tooska ah ee habka qaadista. | |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Xiisadda qaybta leexinta ee habka soo noqoshada.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc. | |

| T5 = ( Ca × T5-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T5 = ( Ca × T6 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T5 = ( 1.27 × 63.6 ) + ( 0.15 × 0.35 × 1.7 ) × ( 5.9 + 60 ) = 86.7 |

-

Wadarta xiisadda suunka TWS (T6)

| FORMULA | TWS = T6 = TN-1 + FBW × LP × ( WB + WP ) |

| Wadarta xiisadda qaybta tooska ah ee habka qaadista. | |

|

| T6 = T6-1 + FBW × LP × ( WB + WP ) |

|

| T6 = T5 + FBW × LP × ( WB + WP ) |

|

| T6 = 86.7 + 0.35 × 2 × ( 5.9 + 60 ) = 132.8 (Kg / M) |

|

|

|

-

Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

|

| TA = 2118 × 1.0 × 0.95 = 2012 (Kg / M) |

|

| Sababtoo ah qiimaha TA ayaa ka weyn TW;Sidaa darteed, qaadashada suunka gudbinta ee Taxanaha 500B waa xulasho badbaado leh oo habboon. |

-

Fadlan tixraac kala dheeraynta Sprocket ee HS-500 ee cutubka Sprocket-ka Drive;fogaanta ugu badan ee sprocket waa ku dhawaad 145mm.

-

Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TWS + SW ) ×BW |

| SL = ( 132.8 + 11.48 ) × 0.5 = 72.14 (Kg) | |

| FORMULA | DS = 5 × 10-4 × [ ( SL × SB3 ) / ( E × I ) ] |

| DS = 5 × 10-4 × [ ( 72.14 × 6003 ) / ( 19700 × 174817 ) ] = 0.002 (mm) | |

| Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka. |

-

Xisaabinta torque usheeda dhexe - TS

| FORMULA | TS = TWS × BW × R |

| TS = 132.8 × 0.5 × 92.5 = 6142 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 50mm × 50mm uu yahay badbaado iyo xulasho habboon. |

-

Xisaabinta xoogga faraska - HP

| FORMULA | HP = 2.2 × 10-4 × [ ( TS × V / R ) ] |

| HP = 2.2 × 10-4 × [ ( 6142 × 4 ) / 95] = 0.057 ( HP ) | |

| Guud ahaan, tamarta makaanikada ee wareejinta wareejintu waxay lumin kartaa 30% inta lagu jiro hawlgalka. | |

| MHP = [0.057 / ( 100 - 30 ) ] × 100 = 0.08 ( HP ) | |

| Qaadashada matoorka wadista 1/4HP waa doorashada saxda ah. |

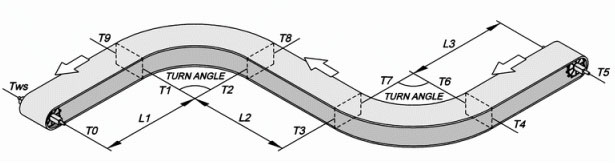

Gaadhiga Taxanaha ah

Habka wareejinta isxigxiga ee isxigxiga waxa laga dhisay laba qalab qaada 90 darajo oo leh jihada iska soo horjeeda.Xargaha gashanaya ee soo laabashada iyo dariiqa qaadida labaduba waxay ka samaysan yihiin walxo HDPE.ballaca suunka wax qaada waa 300mm;Waxay qabataa suunka HS-300B iyo sprockets leh 12 ilkood.Dhererka qaybta orodka tooska ah waa 2M ee dhamaadka shaqo la'aanta, 600mm ee aagga wadajirka ah, iyo 2M ee dhamaadka wadista.Dhexdiisu waa 750mm.Qodobka is jiid-jiidka ee xargaha iyo suunka waa 0.15.Walxaha rarida waa sanduuqyo balaastiig ah oo 40Kg/M2 ah.Xawaaraha hawlgalku waa 5M/daqiiqo, wuxuuna ku shaqeeyaa jawiga qalalan.Xisaabinta la xidhiidha waa sidan soo socota.

-

Xisaabinta wadarta xiisadda unugga - TWS

| FORMULA | TWS = ( TN ) |

|

| T0 = 0 |

| Wadarta xiisadda qaybta wadista ee habka qaadista. | |

|

| T1 = WB + FBW × LR × WB |

|

| T1 = 5.9 + 0.35 × 2 × 5.9 = 10.1 |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Xiisadda qaybta leexinta ee habka soo noqoshada.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc. | |

| T2 = ( Ca × T2-1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( Ca × T1 ) + ( Cb × FBW × RO ) × WB | |

| T2 = ( 1.27 × 10.1 ) + ( 0.15 × 0.35 × 1.05 ) × 5.9 = 13.15 | |

| FORMULA | TN = TN-1 + FBW × LR × WB |

| Xiisadda qaybta tooska ah ee habka soo noqoshada. | |

| T3 = T3-1 + FBW × LR × WB | |

| T3 = T2 + FBW × LR × WB | |

| T3 = 13.15 + ( 0.35 × 0.6 × 5.9 ) = 14.3 | |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × WB |

| Xiisadda qaybta leexinta ee habka soo noqoshada.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc. | |

| T4 = ( Ca × T4-1 ) + ( Cb × FBW × RO ) × WB | |

| TN = ( Ca × T3 ) + ( Cb × FBW × RO ) × WB | |

| T4 = ( 1.27 × 14.3 ) + ( 0.15 × 0.35 × 1.05 ) × 5.9 = 18.49 | |

| FORMULA | TN = TN-1 + FBW × LR × WB |

| Xiisadda qaybta tooska ah ee habka soo noqoshada. | |

| T5 = T5-1 + FBW × LR × WB | |

| T5 = T4 + FBW × LR × WB | |

| T5 = 18.49 + ( 0.35 × 2 × 5.9 ) = 22.6 | |

| FORMULA | TN = TN-1 + FBW × LP × ( WB + WP ) |

| Xiisadda qaybta tooska ah ee habka qaadista. | |

| T6 = T6-1 + FBW × LP × ( WB + WP ) | |

| T6 = T5 + FBW × LP × ( WB + WP ) | |

| T6 = 22.6 + [ ( 0.35 × 2 × ( 5.9 + 40 ) ] = 54.7 | |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Xiisadda qaybta leexinta ee habka qaadista.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc | |

| T7 = ( Ca × T7-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T7 = ( Ca × T6 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T7 = ( 1.27 × 54.7 ) + ( 0.15 × 0.35 × 1.05 ) × ( 40 + 5.9 ) = 72 | |

| FORMULA | TN = TN-1 + FBW × LP × ( WB + WP ) |

| Xiisadda qaybta tooska ah ee habka qaadista. | |

| T8 = T8-1 + FBW × LP × ( WB + WP ) | |

| TN = T7 + FBW × LP × ( WB + WP ) | |

| T8 = 72 + [ ( 0.35 × 0.5 × ( 40 + 5.9 ) ] = 80 | |

| FORMULA | TN = ( Ca × TN-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) |

| Xiisadda qaybta leexinta ee habka qaadista.Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc | |

| T9 = ( Ca × T9-1 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T9 = ( Ca × T8 ) + ( Cb × FBW × RO ) × ( WB + WP ) | |

| T9 = ( 1.27 × 80 ) + ( 0.15 × 0.35 × 1.05 ) × ( 40 + 5.9 ) =104 |

- Wadarta xiisadda suunka TWS (T6)

| FORMULA | TWS = T10 |

| Wadarta xiisadda qaybta tooska ah ee habka qaadista. | |

| TN = TN-1 + FBW × LP × ( WB + WP ) | |

| T10 = T10-1 + FBW × LP × ( WB + WP ) | |

| T10 = 104 + 0.35 × 2 × ( 5.9 + 40 ) = 136.13 (Kg / M) |

-

Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

| TA = 2118 × 1.0 × 0.95 = 2012 (Kg / M) | |

| Sababtoo ah qiimaha TA ayaa ka weyn TW;Sidaa darteed, qaadashada suunka gudbinta ee Taxanaha 300B waa xulasho badbaado leh oo habboon. |

-

Fadlan tixraac kala dheeraynta Sprocket ee cutubka Sprockets Drive;fogaanta ugu badan ee sprocket waa ku dhawaad 145mm.

-

Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TWS + SW ) × BW |

| SL = ( 136.13 + 11.48 ) × 0.3 = 44.28 (Kg) | |

| FORMULA | DS = 5 × 10-4 × [ ( SL × SB3 ) / ( E x I ) ] |

| DS = 5 × 10-4 ×[ ( 44.28 × 4003 ) / ( 19700 × 174817 ) = 0.000001 (mm) | |

| Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka. |

-

Xisaabinta torque usheeda dhexe - Ts

| FORMULA | TS = TWS × BW × R |

| TS = 136.3 × 0.3 × 92.5 = 3782.3 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 38mm × 38mm uu yahay badbaado iyo xulasho habboon. |

-

Calc, ulat, io, n of horsepower - HP

| FORMULA | HP = 2.2 × 10-4 × [( TS × V) / R] |

| HP = 2.2 × 10-4 × [( 3782.3 × 5) / 92.5] = 0.045 (Hp) | |

| Guud ahaan, tamarta makaanikada ee gudbiyaha wadista dhexe waxa laga yaabaa inay lumiso ilaa 30% inta lagu jiro hawlgalka. | |

| MHP = [0.045 / ( 100 - 30 ) ] × 100 = 0.06 ( HP ) | |

| Qaadashada matoorka wadista 1/4HP waa doorashada saxda ah. |

Wareegtada Spiral

Sawirada kor ku xusan waxay tusaale u yihiin habka wareejinta wareega ee leh saddex lakab.Xargaha dariiqyada qaada iyo soo laabashada waxay ka samaysan yihiin walxo HDPE ah.Wadarta guud ee ballaca suunka waa 500mm waxaana la qaataa HS-300B-HD iyo sprockets leh 8 ilkood.Dhererka qaybta qaadista tooska ah ee darawalnimada iyo dhamaadka wadida waa 1 mitir siday u kala horreeyaan.Dhexdeeda wareeggeedii waa 1.5M, daabulida walxahana waa sanduuqyada boostada 50Kg/M2.Xawaaraha hawl-qaadistu waa 25M/daqiiqo, u janjeedho joogga 4M oo ku shaqeeya deegaanka qallalan.Xisaabinta la xidhiidha waa sidan soo socota.

-

Xisaabinta wadarta xiisadda unugga - TWS

| FORMULA | TW = TB × FA |

|

| TWS = 958.7 × 1.6 = 1533.9 (Kg / M) |

|

| |

| FORMULA | TB = [ 2 × R0 × M + ( L1 + L2 ) ] ( WP + 2 WB ) × FBW + ( WP × H ) |

|

| TB = [ 2 × 3.1416 × 2 × 3 + ( 1 + 1 ) ] ( 50 + 2 × 5.9 ) × 0.35 + ( 50 × 2 ) |

| TB = 958.7 (Kg / M) |

- Xisaabinta xiisadda la oggol yahay ee cutubka - TA

| FORMULA | TA = BS × FS × FT |

| TA = 2118 × 1.0 × 0.95 = 2012 (Kg / M) | |

| Sababtoo ah qiimaha TA ayaa ka weyn TW;Sidaa darteed, qaadashada suunka Taxanaha 300B-HD waa xulasho badbaado leh oo habboon. |

- Fadlan tixraac kala dheereynta Sprocket ee HS-300 ee cutubka Sprockets Drive;fogaanta ugu badan ee sprocket waa ku dhawaad 145mm.

- Saamiga leexinta ee usheeda dhexe - DS

| FORMULA | SL = ( TWS + SW ) × BW |

| SL = ( 1533.9 + 11.48 ) × 0.5 = 772.7 (Kg) | |

| FORMULA | DS = 5 × 10-4 ×[ ( SL × SB3 ) / ( E × I ) ] |

| DS = 5 × 10-4 ×[ ( 772.7 × 6003 ) / ( 19700 × 174817 ) ] = 0.024 (mm) |

- Haddii natiijada xisaabinta ay ka yar tahay qiimaha caadiga ah ee ku taxan Shaxda leexinta;qaadashada laba xabo oo kubbada ah ayaa ku filan nidaamka.

- Xisaabinta torque usheeda dhexe - TS

| FORMULA | TS = TWS × BW × R |

| TS = 1533.9 × 0.5 × 92.5 = 70942.8 (kg - mm) | |

| Marka la barbar dhigo Qodobka ugu sarreeya ee Torque ee qaybta Xulashada Shaft, waxaan ognahay in isticmaalka shafka laba jibaaran ee 38mm × 38mm uu yahay badbaado iyo xulasho habboon. |

- Xisaabinta fardaha - HP

| FORMULA | HP = 2.2 × 10-4 × [( TS × V) / R] |

| HP = 2.2 × 10-4 × [ ( 70942.8 × 4 ) / 60 = 1.04 (HP) | |

| Guud ahaan, tamarta makaanikada ee gudbiyaha wadista dhexe waxa laga yaabaa inay lumiso ilaa 40% inta lagu jiro hawlgalka. | |

| MHP = [ 1.04 / ( 100 - 40 ) ] × 100 = 1.73 ( HP ) | |

| Qaadashada matoorka wadista 2HP waa doorashada saxda ah. |