Beddelka Cutubyada

| Ingiriisi (USA) Cutubka X | Ku dhufo | = Halbeegga cabbirka | X ku dhufo | = Ingiriisi (USA). | ||

| Qiyaasta toosan | in | 25.40 | mm | 0.0394 | in | Qiyaasta toosan |

| in | 0.0254 | m | 39.37 | in | ||

| ft | 304.8 | mm | 0.0033 | ft | ||

| ft | 0.3048 | m | 3.281 | ft | ||

| Cabbirka labajibbaaran | gudaha2 | 645.2 | mm2 | 0.00155 | gudaha2 | Cabbirka labajibbaaran |

| gudaha2 | 0.000645 | m2 | 1550.0 | gudaha2 | ||

| ft2 | 92.903 | mm2 | 0.00001 | ft2 | ||

| ft2 | 0.0929 | m2 | 10.764 | ft2 | ||

| Cabbirka Cubic | ft3 | 0.0283 | m3 | 35.31 | ft3 | Cabbirka Cubic |

| ft3 | 28.32 | L | 0.0353 | ft3 | ||

| Heerka Xawaaraha | ft/s | 18.29 | m / daq | 0.0547 | ft/s | Heerka Xawaaraha |

| ft / min | 0.3048 | m / daq | 3.281 | ft / min | ||

| Avoirdupois Miisaanka | lb | 0.4536 | kg | 2.205 | lb | Avoirdupois Miisaanka |

| lb / ft3 | 16.02 | kg / m3 | 0.0624 | lb / ft3 | ||

| Kartida | lb | 0.4536 | kg | 2.205 | lb | Kartida |

| lb | 4.448 | Newton (N) | 0.225 | lb | ||

| kg | 9.807 | Newton (N) | 0.102 | kg | ||

| lb / ft | 1.488 | kg / m | 0.672 | lb / ft | ||

| lb / ft | 14.59 | N/m | 0.0685 | lb / ft | ||

| kg - m | 9.807 | N/m | 0.102 | kg - m | ||

| Torque | gudaha - lb | 11.52 | kg - mm | 0.0868 | gudaha - lb | Torque |

| gudaha - lb | 0.113 | N - m | 8.85 | gudaha - lb | ||

| kg - mm | 9.81 | N - mm | 0.102 | kg - mm | ||

| Wareega Inertia | gudaha4 | 416.231 | mm4 | 0.0000024 | gudaha4 | Wareega Inertia |

| gudaha4 | 41.62 | cm4 | 0.024 | gudaha4 | ||

| Cadaadis / Cadaadis | lb / in2 | 0.0007 | kg / mm2 | 1422 | lb / in2 | Cadaadis / Cadaadis |

| lb / in2 | 0.0703 | kg / cm2 | 14.22 | lb / in2 | ||

| lb / in2 | 0.00689 | N / mm2 | 145.0 | lb / in2 | ||

| lb / in2 | 0.689 | N / cm2 | 1.450 | lb / in2 | ||

| lb / ft2 | 4.882 | kg / m2 | 0.205 | lb / ft2 | ||

| lb / ft2 | 47.88 | N/m2 | 0.0209 | lb / ft2 | ||

| Awood | HP | 745.7 | watt | 0.00134 | HP | Awood |

| ft - lb / min | 0.0226 | watt | 44.25 | ft - lb / min | ||

| Heerkulka | °F | TC = ( °F - 32 ) / 1.8 | Heerkulka | |||

Astaanta BDEF

| Astaanta | Unug | |

| BS | Gaadhida suunka Xoojinta | Kg/M |

| BW | Balaadhka suunka | M |

Qeexida Astaanta C

| Astaanta | Unug | |

| Ca | Eeg shaxda FC | ---- |

| Cb | Eeg shaxda FC | ---- |

D Qeexida Astaanta

| Astaanta | Unug | |

| DS | Saamiga leexinta usheeda dhexe | mm |

E Astaanta Qeexida

| Astaanta | Unug | |

| E | Heerka Kordhinta Shaft | Gpa |

F Astaanta Qeexida

| Astaanta | Unug | |

| FC | Isku xidhka Kala-baxa Inta u dhaxaysa suunka suunka iyo Hoos-u-jiid Strip | ---- |

| FBP | Iskuxidhka Kala-jaridda ee udhaxeysa alaab-qaadista iyo dusha suunka | ---- |

| FBW | Isku-dubbaridka Qalabka Taageerada suunka | ---- |

| FA | Isku-xidhka Wax-ka-beddelka | ---- |

| FS | Isku-dubbaridka Xoog-Xasidda oo wax laga beddelay | ---- |

| FT | Kordhiye suunka Heerkulka Isku-xidhka Wax-ka-beddelka | --- |

Astaanta HILM

| Astaanta | Unug | |

| H | Kor-u-qaadista kor u janjeerta joogga. | m |

| HP | Awood faras | HP |

I Astaanta Qeexida

| Astaanta | Unug | |

| I | Daqiiqadii Inertia | mm4 |

L Qeexida Astaanta

| Astaanta | Unug | |

| L | Fogaanta Gaadhida (Barta dhexe ee laga bilaabo usha wadista ilaa shafka Idler) | M |

| LR | Jidka Soo Celinta Toosan Qaybta Dhererka | M |

| LP | Qaado Jidka Toosan ee Orod Qaybta Dhererka | M |

M Astaanta Qeexida

| Astaanta | Unug | |

| M | Heerka lakabka wareejinta Spiral | ---- |

| MHP | Matoorka Horsepower | HP |

Astaanta PRS

| Astaanta | Unug | |

| PP | Boqolkiiba Meesha Cabbirka Aagga ee Alaabtu urursatay | ---- |

Qeexida Astaanta R

| Astaanta | Unug | |

| R | Sprocket Radius | mm |

| RO | Radius ka baxsan | mm |

| rpm | Kacdoon Daqiiqadiiba | rpm |

Qeexida Astaanta S

| Astaanta | Unug | |

| SB | Farqiga u dhexeeya Dhalmada | mm |

| SL | Wadarta guud ee Shaft loading | Kg |

| SW | Miisaanka Shaft | Kg/M |

Astaanta TVW

| Astaanta | Unug | |

| TA | Jeexiyaha Suunka Cutubka Kacsanaanta La Oggolyahay | Kg/M |

| TB | Aragtida Unug suunka Gaadhida | Kg/M |

| TL | Gaadhida suunka Cutubka suunka xiisadda Sag. | Kg/M |

| TN | Xiisadda Qaybta | kg/M |

| TS | Torque | Kg.mm |

| TW | Gaadhida suunka wadarta guud ee kacsanaanta | Kg/M |

| TWS | Nooca Gaarka ah ee wareejinta suunka Cutubka wadarta xiisadda | Kg/M |

V Qeexida Astaanta

| Astaanta | Unug | |

| V | Xawaaraha sahayda | M/min |

| VS | Xawaaraha Aragtida | M/min |

W Astaanta Qeexida

| Astaanta | Unug | |

| WB | Gaadhida suunka Culayska | Kg/M2 |

| Wf | Isku-buuqa Isku-buuqa Kaabista ee Urursan | Kg/M2 |

| WP | Gaadhida Suunka Qaada Cutubka Alaabta |

|

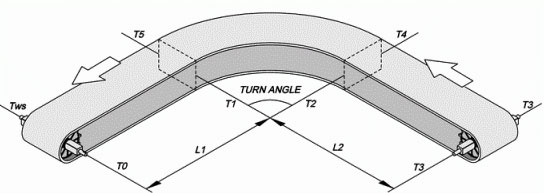

Riix iyo laba jiho

Riixiyaha ama qaadiyaha laba-geesoodka ah, xiisadda suunka ayaa ka sarrayn doonta qaadaha toosan ee caadiga ah;sidaas darteed, shafka ee labada daraf ayaa lagama maarmaan u ah in loo tixgeliyo sida wadiiqooyinka wadista oo la hoosgeliyo xisaabinta.Guud ahaan, waxay ku dhowdahay 2.2 jeer qodobka khibradda si loo helo wadarta xiisadda suunka.

FORMULA: TWS = 2.2 TW = 2.2 TB X FA

TWS ee cutubkan waxay ka dhigan tahay xisaabinta xiisadda qaadaha labada dhinac ama riixaha.

Xisaabinta leexashada

Xisaabinta xiisadda TWS ee wareejinta wareejinta waa in la xisaabiyo xiisadda urursan.Sidaa darteed, xiisadda qayb kasta oo qaadis ah waxay saameyn doontaa qiimaha wadarta xiisadda.Taas macnaheedu waa, wadarta xiisaddu waxay ka soo ururtay bilawga qaybta wadista ee habka soo noqoshada, iyada oo la raacayo habka dib u noqoshada qaybta aan shaqayn, ka dibna u gudub qaybta qaadista qaybta wadista.

Meesha naqshadeynta cutubkan waa T0 oo ku hoos jirta shafka wadista.Qiimaha T0 wuxuu la mid yahay eber;Waxaan ka xisaabinay qayb kasta T0.Tusaale ahaan, qaybta ugu horreysa ee tooska ah ee soo noqoshada waxay ka socotaa T0 ilaa T1, taas oo macnaheedu yahay xiisadda ururtay ee T1.

T2 waa xiisadda urursan ee booska leexinta ee habka soo noqoshada;Si kale haddii loo dhigo, waa xiisadda ururtay ee T0, T1 iyo T2.Fadlan sida ku cad sawirka kore oo qiyaas xiisadda ururtay ee qaybaha dambe.

FORMULA: TWS = ( T6 )

Wadarta xiisadda qaybta wadista ee habka qaadista.

TWS ee cutubkan waxay ka dhigan tahay xisaabinta xiisadda wareejinta.

FORMULA: T0 = 0

T1 = WB + FBW X LR X WB

Xiisada catenary sag ee booska wadista.

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X WB

Xiisadda qaybta leexinta ee habka soo noqoshada.

Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc.

T2 = ( Ca X T2-1 ) + ( Cb X FBW X RO ) X WB

TN = ( Ca X T1 ) + ( Cb X FBW X RO ) X WB

FORMULA: TN = TN-1 + FBW X LR X WB

Xiisadda qaybta tooska ah ee habka soo noqoshada.

T3 = T3-1 + FBW X LR X WB

T3 = T2 + FBW X LR X WB

FORMULA: TN = TN-1 + FBW X LP X ( WB + WP )

Xiisadda qaybta tooska ah ee habka qaadista.

T4 = T4-1 + FBW X LP X ( WB + WP )

T4 = T3 + FBW X LP X ( WB + WP )

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

Xiisadda qaybta leexinta ee habka qaadista.

Qiimaha Ca iyo Cb, fadlan tixraac shaxda Fc.

T5 = ( Ca X T5-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

T5 = ( Ca X T4 ) + ( Cb X FBW X RO ) X ( WB + WP )

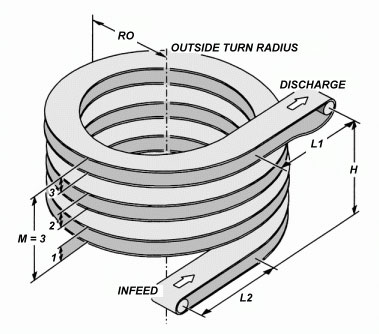

Wareegtada Spiral

FORMULA: TWS = TB × FA

TWS ee cutubkan waxa ay ka dhigan tahay xisaabinta xajinta wareegtada.

FORMULA: TB = [ 2 × RO × M + ( L1 + L2 ) ] ( WP + 2WB ) × FBW + ( WP × H )

FORMULA: TA = BS × FS × FT

Fadlan tixraac Shaxda FT iyo Shaxda FS.

Tusaale wax ku ool ah

Isbarbardhigga TA iyo Qaaxada, iyo xisaabinta kale ee la xiriirta waxay la mid yihiin noocyada kale ee qaadeyaasha.Waxaa jira xaddidaadyo iyo xeerar gaar ah oo ku saabsan naqshadeynta iyo dhismaha wareejinta wareegyada.Sidaa darteed, markaad codsanayso HONGSBELT spiral ama u rogid suumanka nidaamka gudbinta wareega, waxaan kugula talineynaa inaad tixraacdo buug-gacmeedka HONGSBELT oo aad la xiriirto waaxdayada adeegga farsamada wixii macluumaad iyo faahfaahin dheeraad ah.

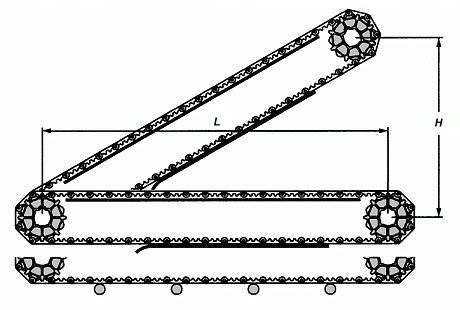

Xiisadda Cutubka

FORMULA: TB = [ ( WP + 2WB ) X FBW ] XL + ( WP XH )

Haddii alaabta la qaadayo ay la socdaan sifada ururinta, xoogga is jiid jiidka ee kor u kaca inta lagu jiro rarista alaabada waa inay hoos u dhigtaa xisaabinta.

FORMULA: TB = [ ( WP + 2WB ) X FBW + Wf ] XL + ( WP XH )

FORMULA: Wf = WP X FBP X PP

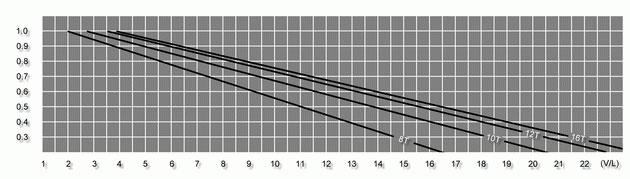

Xiisad La Ogolyahay

Sababtoo ah maaddada kala duwan ee suunka ayaa leh awood jilicsan oo kala duwan taas oo ay saameyn doonto kala duwanaanta heerkulka.Sidaa darteed, xisaabinta xiisadda la oggol yahay ee TA waxaa loo isticmaali karaa in lagu barbardhigo wadarta suunka TW.Natiijadan xisaabinta ayaa kaa caawin doonta inaad samayso doorashada saxda ah ee xulashada suunka oo aad la jaanqaadi doonto baahida qaadaha.Fadlan ka eeg Shaxda FS iyo Miiska T ee ku yaal menu-ka bidix.

FORMULA: TA = BS X FS X FT

BS = Gaadhida suunka Xoojinta (Kg / M)

FS iyo FT Waxay u jeedaan Shaxda FS iyo Shaxda FT

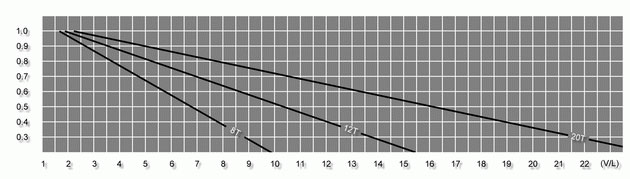

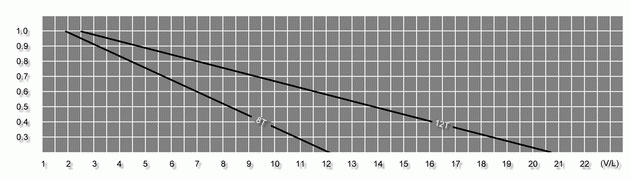

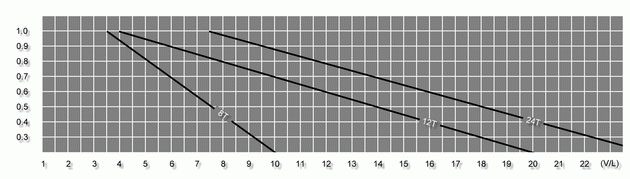

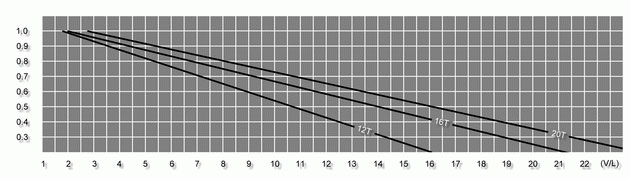

Shaxda Fs

Taxanaha HS-100

Taxanaha HS-200

Taxanaha HS-300

Taxanaha HS-400

Taxanaha HS-500

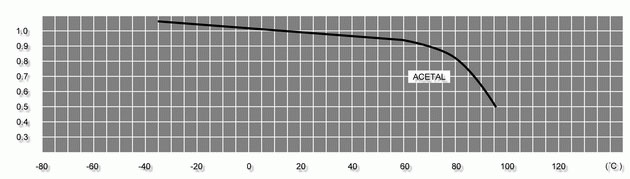

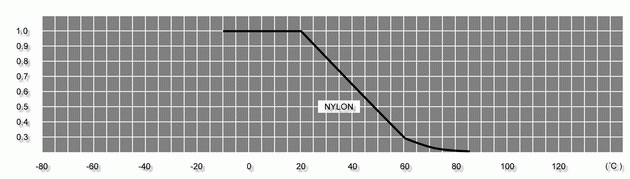

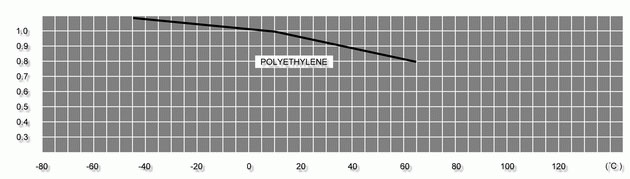

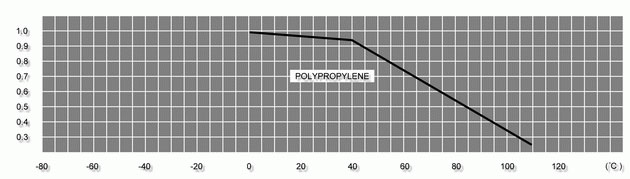

Shaxda Ts

Acetal

Nayloon

Polyethylene

Polypropylene

Xulashada Shaft

FORMULA: SL = ( TW + SW ) ?BW

Miisaanka Miisaanka Shaft ee Wadid/Idler - SW

| Cabirka Shaft | Miisaanka Shaft (Kg/M) | |||

| Birta Kaarboonka | Bir daxal laheyn | Aluminium Aloy | ||

| Usheeda dhexe | 38mm | 11.33 | 11.48 | 3.94 |

| 50mm | 19.62 | 19.87 | 6.82 | |

| Wareegga Wareegga | 30mm?/FONT> | 5.54 | 5.62 | 1.93 |

| 45mm?/FONT> | 12.48 | 12.64 | 4.34 | |

Ka leexashada Shaft Drive/Idler - DS

Aan Lahayn Dhexdhexaadiye

FORMULA

DS = 5 ?10-4 ( SL ?SB3 / E ?/FONT> I)

Iyada oo Dhexdhexaad ah

FORMULA

DS = 1 ?10-4 ( SL ?SB3 / E ?I )

Balaadhan ee Shaft Drive - E

| Cutubka: Kg/mm2 | |||

| Qalab | Bir daxal laheyn | Birta Kaarboonka | Aluminium Aloy |

| Heerka Laastikada ee Shaft Drive | 19700kii | 21100 | 7000 |

Daqiiqada Inertia - I

| Dhexroorka sprocket wadista | Daqiiqada inertia ee usheeda dhexe (mm4) | |

| Shaft Square | 38mm | 174817 |

| 50mm | 1352750 | |

| Wareegga Wareegga | 30mm?/FONT> | 40791 |

| 45mm?/FONT> | 326741 | |

Xisaabinta Shaft Torque - TS

| FORMULA | TS = TW ?BW ?R |

Qiimaha xisaabinta ee kore, fadlan la barbar dhig shaxda hoose si aad u doorato shafka wadista ugu fiican.Haddii qulqulka usheeda dhexe uu weli aad u xoog badan yahay, sprocket-ka yar ayaa loo isticmaali karaa si loo yareeyo qulqulka, iyo sidoo kale dhaqaalaha qiimaha ugu muhiimsan ee usheeda dhexe iyo dhalista.

Isticmaalka sprocket yar si aad ugu habboonaato usheeda dhexe ee leh dhexroorka weyn si loo yareeyo qulqulka, ama isticmaalka sprocket ka weyn si aad ugu habboonaato usheeda dhexe ee leh dhexroor yar si loo kordhiyo qulqulka.

Qodobka ugu sarreeya ee Torque ee Shaft Drive

| Torque | Qalab | Dhexroorka Joornaalka (mm) | ||||||

| 50 | 45 | 40 | 35 | 30 | 25 | 20 | ||

| Kg-mm x 1000 | Bir daxal laheyn | 180 | 135 | 90 | 68 | 45 | 28 | 12 |

| Birta Kaarboonka | 127 | 85 | 58 | 45 | 28 | 17 | 10 | |

| Aluminium Aloy | -- | -- | -- | 28 | 17 | 12 | 5 | |

Awood faras

Haddii mootada loo doorto matoorka yareeya geerka, saamiga farasku waa inuu ka weynaadaa alaabta sidda iyo wadarta xoogga xajinta ee dhalisa inta suunka socdo.

Awoodda Horse (HP)

| FORMULA | = 2.2 × 10-4 × TW × BW × V |

| = 2.2 × 10-4 ( TS × V / R ) | |

| = Watts × 0.00134 |

Watts

| FORMULA | = ( TW × BW × V ) / ( 6.12 × R) |

| = ( TS × V) / ( 6.12 × R) | |

| = HP × 745.7 |

Shaxda FC

| Qalabka tareenka | Heerkulka | FC | ||

| Qalabka suunka | Qalalan | Qoyan | ||

| HDPE / UHMW | -10°C ~ 80°C | PP | 0.10 | 0.10 |

| PE | 0.30 | 0.20 | ||

| Actel | 0.10 | 0.10 | ||

| Nayloon | 0.35 | 0.25 | ||

| Acetal | -10°C ~ 100°C | PP | 0.10 | 0.10 |

| PE | 0.10 | 0.10 | ||

| Actel | 0.10 | 0.10 | ||

| Nayloon | 0.20 | 0.20 | ||

Fadlan ku barbar dhig alaabta biraha iyo alaabta suunka qaada qaadaha iyo habka rarida meel qalalan ama qoyan si aad u hesho qiimaha FC.

Ca, Cb Qiimaha

| Xagalka Wareegga suunka | Isku xidhka Isku xidhka udhaxeya Weriyaha suunka & Jidka Tareenka | |||||

| FC ≤ 0.15 | FC ≤ 0.2 | FC ≤ 0.3 | ||||

| Ca | Cb | Ca | Cb | Ca | Cb | |

| ≥ 15 ° | 1.04 | 0.023 | 1.05 | 0.021 | 1.00 | 0.023 |

| ≥ 30 ° | 1.08 | 0.044 | 1.11 | 0.046 | 1.17 | 0.048 |

| ≥ 45 ° | 1.13 | 0.073 | 1.17 | 0.071 | 1.27 | 0.075 |

| ≥ 60 ° | 1.17 | 0.094 | 1.23 | 0.096 | 1.37 | 0.10 |

| ≥ 90 ° | 1.27 | 0.15 | 1.37 | 0.15 | 1.6 | 0.17 |

| ≥ 180 ° | 1.6 | 0.33 | 1.88 | 0.37 | 2.57 | 0.44 |

Ka dib markaad ka hesho qiimaha FC miiska FC, fadlan ku beddel xagal qaloocan ee qaadiyaha, waxaadna heli kartaa qiimaha Ca iyo qiimaha Cb.