Cabirka aasaasiga ah

Naqshadeynta habka gudbinta waxaa loo kala qeybiyaa 4 qeybood oo waaweyn kuwaaso kala ah suunka, qeyb wadista/mid aan shaqeyn, qaab dhismeedka taageerada iyo habka wadista.Qaab dhismeedka suunka ayaa lagu qeexay qaybta hore.3-da qaybood ee kale ayaa hoos ku sharxi doona iyadoo tafatiran:

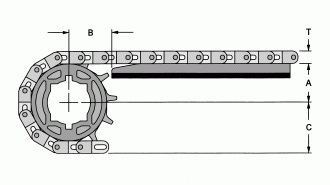

Qaybta X-X'

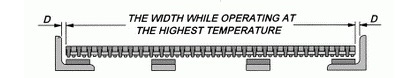

D: 1-10mm

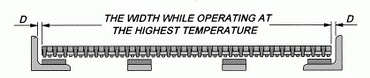

Cabirka suunka ayaa yeelan doona kala duwanaansho sababtoo ah isbeddelka heerkulka.Fadlan tixraac cutubka Xisaabinta Balaadhinta Kulaylka si aad u xaqiijiso cabbirka naqshadaynta.

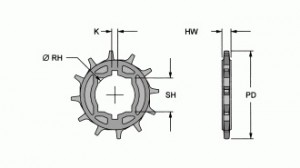

Shaxda cabbirka

| Unug: mm | |||||||||||||

| Sprocket | A | B(daqiiqo) | C (max) | T | K | HW | S-HW | PD | RH | SH | Acetal | SUS304 | |

| Taxanaha 100 | 8T | 57 | 65 | 70 | 16 | 7X7 | 38 | 34 | 133 | 45.5 | 38.5 | ● | ● |

| 10T | 72 | 82 | 86 | 164 | ● | ||||||||

| 12T | 88 | 100 | 103 | 38 | 196 | ● | ● | ||||||

| 16T | 121 | 132 | 136 | 260 | ● | ||||||||

| Taxanaha 200 | 8T | 27 | 33 | 35 | 10 | 6X6 | 22 | 7.5 | 64 | 30.5 | -- | ● | ● |

| 12T | 43 | 50 | 52 | 7X7 | 38 | 34 | 98 | 45.5 | 38.5 | ● | ● | ||

| 20T | 76 | 83 | 85 | 163 | ● | ||||||||

| Taxanaha 300 | 8T | 51 | 62 | 63 | 15 | 7X7 | 12 | -- | 120 | 45.5 | 38.5 | ● | ● |

| 12T | 80 | 82 | 94 | -- | 185 | ● | ● | ||||||

| Taxanaha 400 | 8T | 10 | 14 | 16 | 7 | 3X3 | -- | 4 | 26 | 12.5 | -- | ● | |

| 12T | 16 | 21 | 22 | 4X4 | -- | 38.5 | 25.3 | -- | ● | ||||

| 24T | 35 | 38 | 41 | 8X8 | 25.5 | 12 | 76.5 | 45.5 | 38.5 | ● | ● | ||

| Taxanaha 500 | 12T | 41 | 52 | 53 | 13 | 7X7 | 10.5 | 5 | 93 | 45.5 | 38.5 | ● | ● |

| 24T | 89 | 100 | 102 | 190 | ● | ● | |||||||

Xisaabinta ballaca suunka qaadaha ee heerkulka ugu sarreeya, fadlan tixraac qaacidada xisaabinta ballaadhinta kulaylka / foosha.Habka taageerada ee qaybta wadista gaadiidka, fadlan tixraac qeexida habka taageerada suunka ee waafaqsan naqshadaynta gaadiidka.

Bixinta soo saarista cabbirada gaarka ah ee Steel Sprocket Bore waa mid la aqbali karo.

S-HW waa cabbirka xudunta u ah Sprocket Steel Drive.

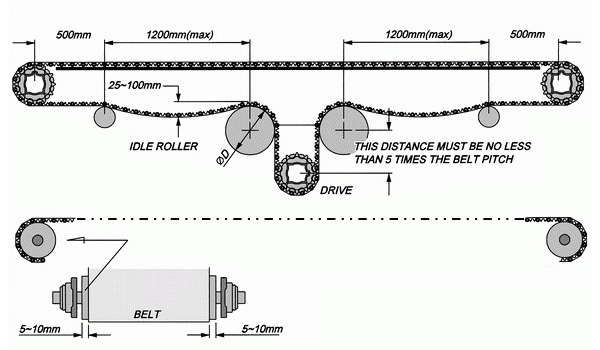

Xarunta Wadida

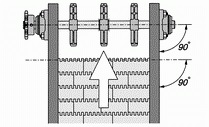

Si aad uga fogaato qaadashada garab istaaga qaybaha aan shaqayn ee labada dhinac.

Dhexroorka ugu yar ee Roller-ka Idler - D ( Jidka soo laabashada )

| Unug: mm | |||||

| Taxane | 100 | 200 | 300 | 400 | 500 |

| íD (min.) | 180 | 150 | 180 | 60 | 150 |

Idler Roller

Qaybta X-X'

Cabirka suunka ayaa yeelan doona kala duwanaansho sababtoo ah isbeddelka heerkulka.Fadlan tixraac Xisaabinta Balaadhinta ee liiska bidix si aad u xaqiijiso cabbirka naqshadaynta.

Shaxda cabbirka

Unug: mm

| Dhexroor Roller (daq.) | A ( daq.) | B ( daq.) | C (max.) | D ( daq.) | E (max.) | |

| Taxanaha 100 | 104 | 76 [1 | 38 [2 | 57 | 3 | 114 |

| Taxanaha 200 | 54 | 40 [1 | 18 [2 | 27 | 3 | 59 |

| Taxanaha 300 | 102 | 69 [1 | 34 [2 | 51 | 3 | 117 |

| Taxanaha 400 | 20 | 19 [1 | 7 [2 | 10 | 2 | 27 |

| Taxanaha 500 | 82 | 56 [1 | 27 [2 | 41 | 3 | 95 |

Saxnaanta

Unug: mm

| Cabbirka Gaadhida (Balac ahaan) | Dhererka | |||||

| ≥ 5M | ≥ 10M | ≥ 15M | ≥ 20M | ≥ 25M | ≥ 30M | |

| ≥ 350 | ± 2.0 | ± 2.5 | ± 2.5 | ± 3.0 | ± 3.0 | ± 3.5 |

| ≥ 500 | ± 2.5 | ± 2.5 | ± 2.5 | ± 3.0 | ± 3.5 | ± 4.0 |

| ≥ 650 | ± 2.5 | ± 2.5 | ± 3.0 | ± 3.5 | ± 4.0 | ± 4.5 |

| ≥ 800 | ± 2.5 | ± 3.0 | ± 3.5 | ± 4.0 | ± 4.5 | ± 5.0 |

| ≥ 1000 | ± 3.0 | ± 3.5 | ± 4.0 | ± 4.5 | ± 5.0 | ± 5.5 |

Marka gaadiidka qaada loo qaabeeyey in uu qaato suunka balaastigga ah ee loo yaqaan HONGSBELT oo leh isku xirka birta, xagasha u dhaxaysa shafka wadista iyo qaab dhismeedka gaadiidku waa in uu ahaadaa mid sax ah si toos ah, si looga hortago qallafsanaanta ulaha birta ah ee aan fiicnayn taas oo keeni karta in suunka uu dhaawacmo sababtoo ah waxa uu sameeyaa. aan si siman u shaqayn.

Xisaabinta Balaadhinta

Inta badan walxuhu waxay leeyihiin ifafaale balaadhinta kulaylka iyo foosha.Sidaa darteed, ifafaale ballaarinta kulaylka iyo foosha walxaha ay sababto isbeddelka heerkulka waa in la tixgeliyaa marka la naqshadeynayo nidaamka gudbinta.

Heerkulka Qalabka suunka

| Qalabka suunka | |||

| Polypropylene | Polyethylene | NYLON | Actel |

| Qiyaasta heerkulka (°C) | |||

| 1 ~ 100 | -60 ~ 60 | -30 ~ 150 | -40 ~ 60 |

Jadwalka sare waa heerka heerkulka caadiga ah ee alaabta caaga ah ee codsiga guud.Heerkulka caadiga ah ee kala duwanaanta agabka suunka HONGSBELT, fadlan tixraac qaybta xogta aasaasiga ah ee Cutubka Alaabta.

Balaadhinta & Shaxda Isbarbardhigga Qandaraaska - e

Cutubka: mm/M/°C

| Qalabka suunka | Qalabka loo isticmaalo Taageerada | Birta | |||||||

| Polyproeylene | Polyethylene | NYLON | Actel | Teflon | HDPE & UHMW | Birta Kaarboonka | Aluminium Aloy | Bir daxal laheyn | |

| 73°C ~ 30°C | 30°C~99°C | ||||||||

| 0.12 | 0.23 | 0.07 | 0.09 | 0.12 | 0.14 | 0.18 | 0.01 | 0.02 | 0.01 |

Balaadhinta & Foomamka Xisaabinta Qandaraasyada

Dhererka iyo ballaca suunka labadaba waxaa saameyn doona isbeddelka heerkulka jawiga, sida suunka ayaa kordhi doona marka heerkulku kordho iyo qandaraas marka heerkulku hoos u dhaco;Qaybtan waa in lagu tixgaliyaa xisaabin ula kac ah marka la naqshadeynayo habka gudbinta.Habka xisaabinta ee kala duwanaanta cabbirku waa sida soo socota.

FORMULA: TC = LI × ( Ku - TI )× e

| Astaanta | Qeexid | Unug |

| TC | Isbeddelka cabbirka | mm |

| TCL | Dhererka isbeddelka heerkulka ka dib | mm |

| TCW | Ballaca heerkulka isbeddelka ka dib | mm |

| LI | Cabirka heerkulka hore | M |

| To | Heerkulka shaqada | °C |

| TI | Heerkulka hore | °C |

Tusaale 1:Suunka gudbinta ee walxaha PP oo cabbirkiisu yahay 18.3m dhererka iyo 3.0m ballaca suunka, bilow heerkulka hawlgalka 21℃.Maxay noqon doontaa natiijada dhererka suunka iyo ballaca heerkulka shaqada ee kor u kaca ilaa 45°C?

TCL = 18.3 × ( 45 - 21 ) × 0.124 = 54.5 (mm)

TCW = 3 × ( 45 - 21 ) × 0.124 = 8.9 (mm)

Marka la eego natiijada xisaabinta, waxaan ognahay in dhererka suunka uu kordhin doono qiyaastii ilaa 55mm ballaca suunkana wuxuu kordhin karaa ku dhawaad 9 mm marka loo eego heerka heerkulka 21 ~ 45 ° C.

Tusaale 2:Suunka gudbinta ee walxaha PE oo cabbirkiisu yahay 18.3m dhererka iyo 0.8m ballaca suunka, bilow heerkulka hawlgalka 10℃.Maxay noqon doontaa natiijada dhererka suunka iyo ballaca heerkulka shaqada ee kor u kaca ilaa -40°C?

TCL = 18.3 × ( - 40 - 10 ) × 0.231 = - 211.36 (mm)

TCW = 0.8 × ( - 40 - 10 ) × 0.231 = - 9.24 (mm)

Laga soo bilaabo natiijada xisaabinta, waxaan ognahay in dhererka suunka uu hoos u dhigi doono ku dhawaad 211.36 mm iyo ballaca suunka ayaa laga yaabaa inuu yareeyo ku dhawaad 9.24mm, hoos heerkulka kala duwan ee 10 ~ -40 ° C.

Horgalayaasha V

| Magaca Kiimikada | Xaaladda Heerkulka | Qalabka suunka | |||

| ACETAL | NYLON | P .E. | P .P . | ||

| Khamriga weli wuu kacsan yahay | 21°C | N | O | O | |

O = OK, N = MAYA